Description

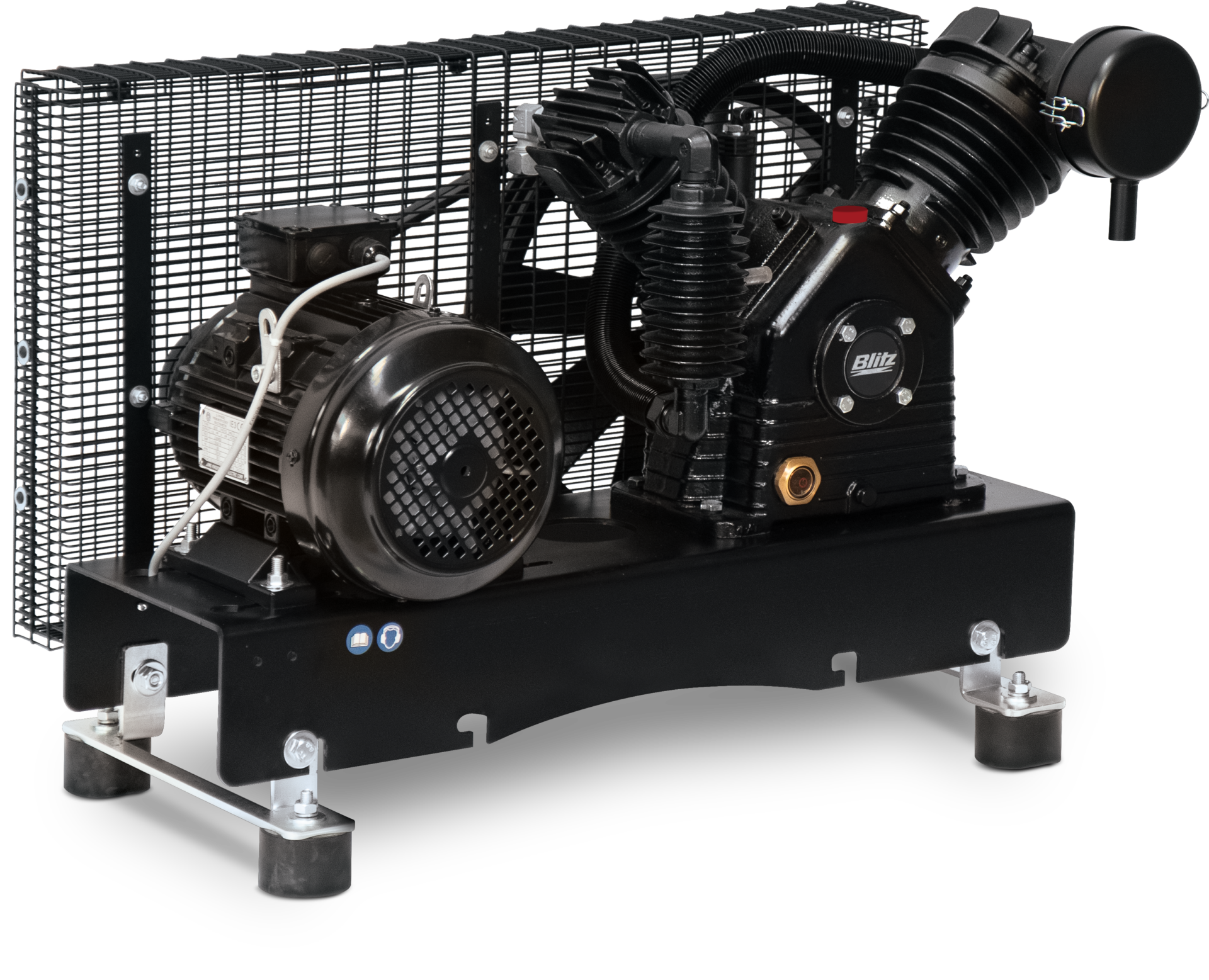

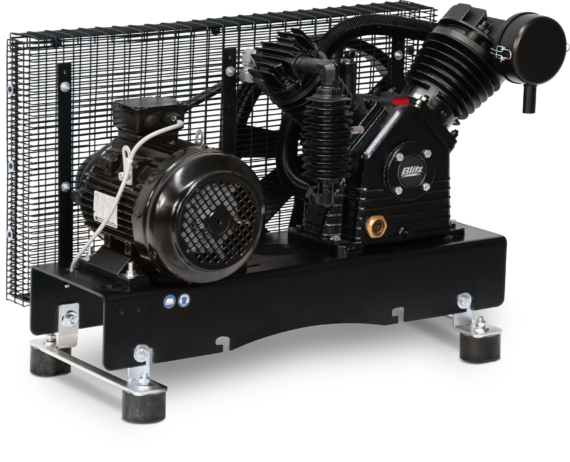

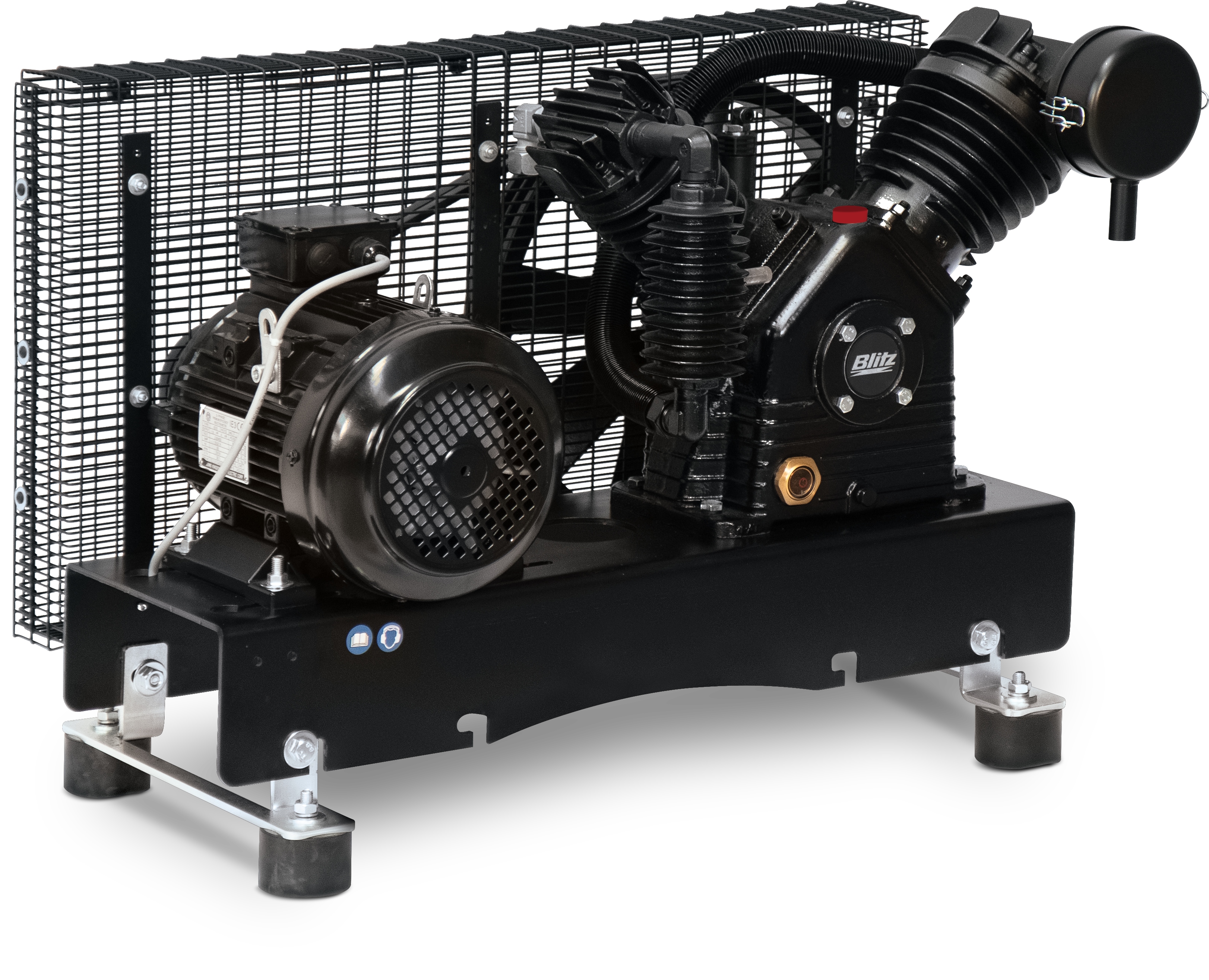

VERSA UNI piston compressors by BLITZ boast efficiency and high-quality workmanship at an attractive price for demanding users of compressed air who require its use on a daily basis. VERSA UNI compressors stand out thanks to their high-performance belt drive.

- Energy efficient motors – IE3 class

- 25% energy savings thanks to 2-stage compression

- Ideal for industrial use in workshops

- Premium piston compressors – made by Blitz

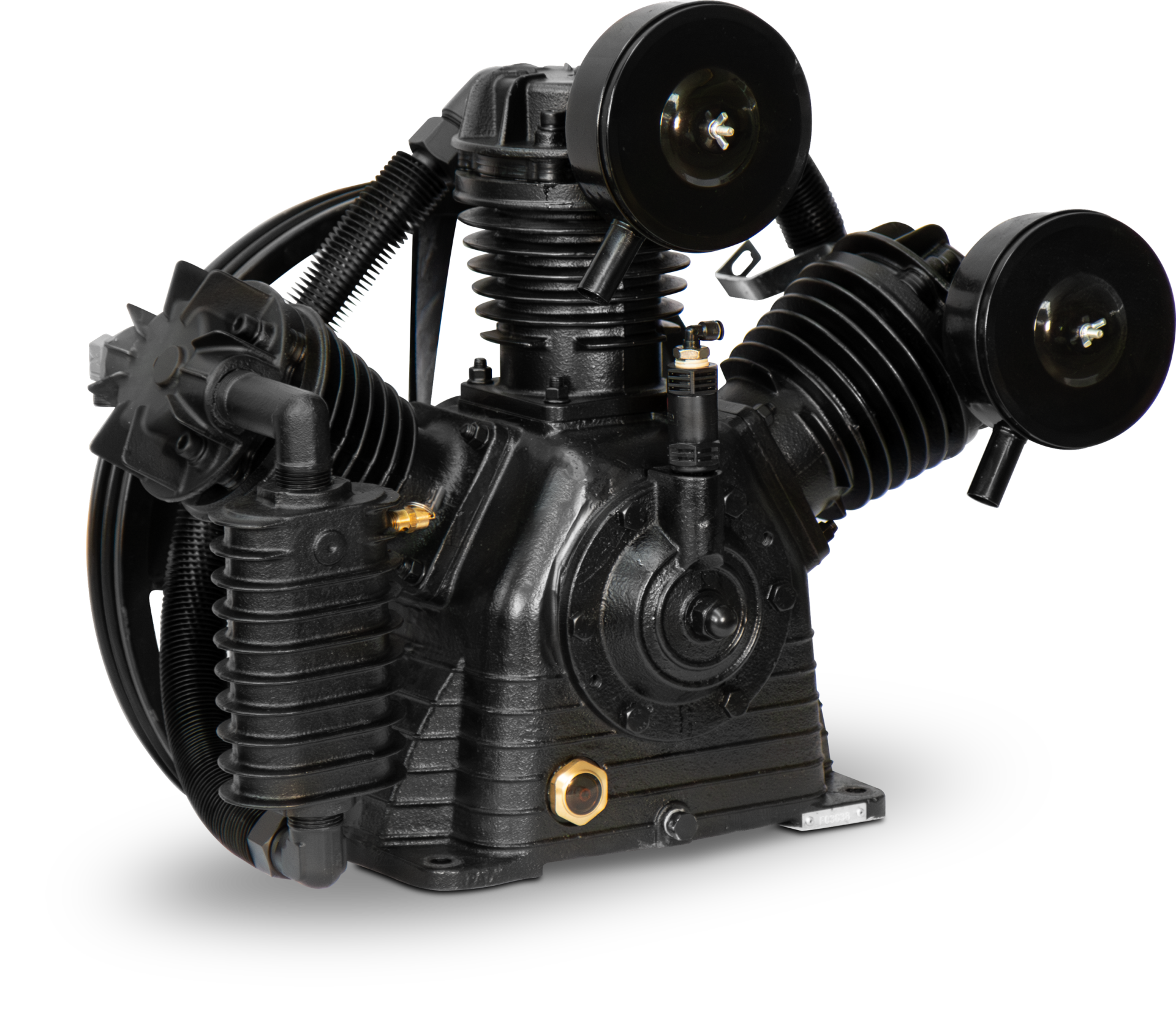

- Intricate plateau honing of cylinders: The special quality of the cylinder surface with its particularly high contact ratio and defined oil content-volume ensures minimal piston ring wear and minimizes oil consumption.

- Maintenance-free reed valves: Simple design, sophisticated performance. Two factors lead to long tool life for VERSA UNI piston compressors.

- The option of fully galvanizing the pressure tank allows you to increase the longevity and thus the value of your VERSA UNI piston compressor.

- Compressed air aftercoolers: Powerful aftercoolers and intermediate coolers, designed using copper piping or aluminium honeycomb, come as standard in all VERSA UNI piston compressors to ensure low compressed air outlet temperatures. This greatly reduces the effort involved in further preparing the compressed air.

- VERSA Uni piston compressors by BLITZ are manufactured to the highest quality standards. This includes using high-quality IP 54-tested electric motors with ISO F-winding. For continuous operation and high switching frequency.

- Freestanding, finely ribbed casting cylinder: This type of layout guarantees the maximum cooling surface. The basis for extremely low operating temperatures and maximum efficiency. That is why VERSA UNI piston compressors are easily used, even in extreme operating conditions.

- Pressure tank with hand hole (manufactured in accordance with AD2000): The easy-to-service design of the VERSA UNI pressure tank with integrated hand hole minimizes the cost for recurring TÜV examinations and facilitates pressure tank cleaning.

- Crankshafts with especially large pin diameters: The generous sizing of the crankshaft journal reduces the specific load of the large end bearings and enables bearing lifetimes that meet the high demands of continuous industrial use.

- Crankcase: Crankcases are manufactured using state-of-the-art computerized machining centers to guarantee optimal dimensional accuracy.

- Low speed: VERSA UNI piston compressors mean high piston displacement at low speed. This guarantees a long service life, low wear, the utmost in smooth running and high efficiency.

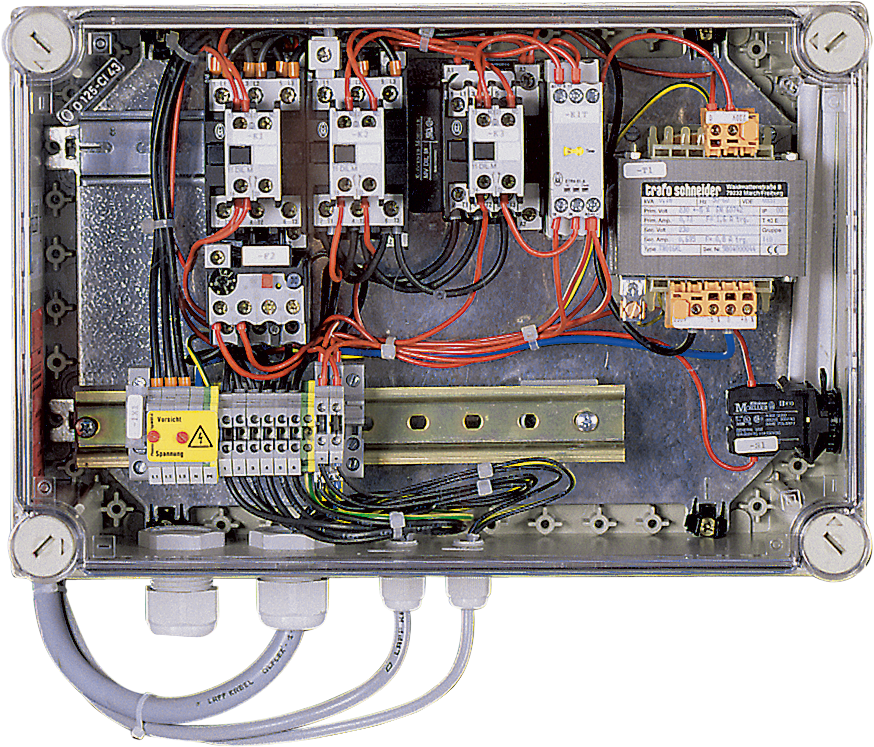

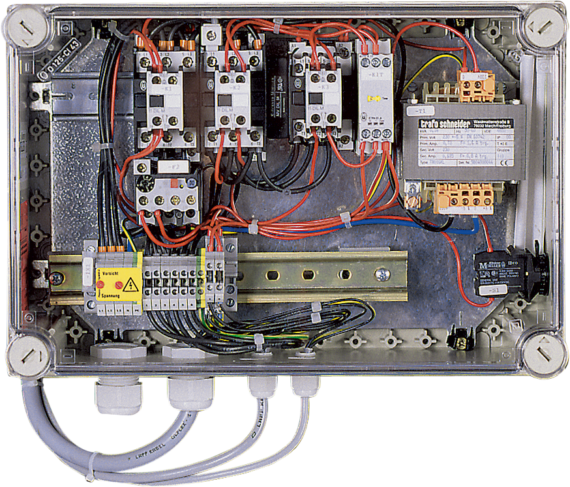

- Fully wired star delta circuit (for wall mounting). Assembly and functional testing takes place at the manufacturing plant, completely eliminating otherwise typical on-site costs. This is a huge advantage compared to loosely supplied ”control kits”.

Accessories:

- Refrigeration dryer – for efficient preparation of compressed air. Dry compressed air containing no corrosive water components is the basis for an efficient compressed air station.

- Filter – effectively frees the compressed air from solid particles. Different filter combinations make it possible to use the compressor in various application environments.

- Oil-water separator – the cost-effective treatment of condensate. Only the oil portion needs to be disposed of, the water can go into the sewer system.

- Steam trap – electronic, level-regulated design for fully automatic air receiver drainage.

To meet all installation requirements, there are stationary VERSA UNI piston compressors with horizontal and vertical air receivers. Vertical pressure tanks are the perfect solution for small rooms and workshops.

VERSA UNI G For modular design with separate pressure tank, or to expand existing systems

Space-saving – For all users of compressed air who do not want to sacrifice performance despite minimal space requirements.

PERFORMANCE TO MEET HIGH STANDARDS IN INDUSTRY

VERSA UNI: The high-performance compressor with extraordinary efficiency and a long service life – especially for the highest of industrial demands, designed for 100% duty cycle. The wide range of applications of the VERSA piston compressors explains the wide variety of products.

FOR NEARLY 100 YEARS …

SYNONYMOUS WITH COMPRESSED AIR

Manufacturing compressors is a long-standing tradition with Blitz. Boasting almost 100 years of experience in compressed air and a highly dedicated staff, we focus on designing and implementing new compressors and compressed air treatment technologies.

Innovative ideas, professional implementation and phenomenal product quality have established the outstanding reputation of Blitz compressors and ensure one thing above all: Satisfied customers.

The right offer for your needs: Based on your compressed air requirements, Blitz compressors will put together the appropriate systems in the combination that is perfect for you.