Description

TWIN piston compressors from BLITZ offer performance and first-class workmanship at an attractive price for all compressed air users with high standards and daily application needs.

In order to meet all installation requirements, there are stationary TWIN piston compressors with horizontal and vertical compressed air reservoir (perfect solution for small rooms and workshops). For areas particularly sensitive to noise we provide designs with sound reduction hoods.

- Premium piston compressors – made by Blitz

- Longevity thanks to full galvanizing equipped as standard

- Energy savings of up to 25% via 2-stage compression

- Perfect for workshops

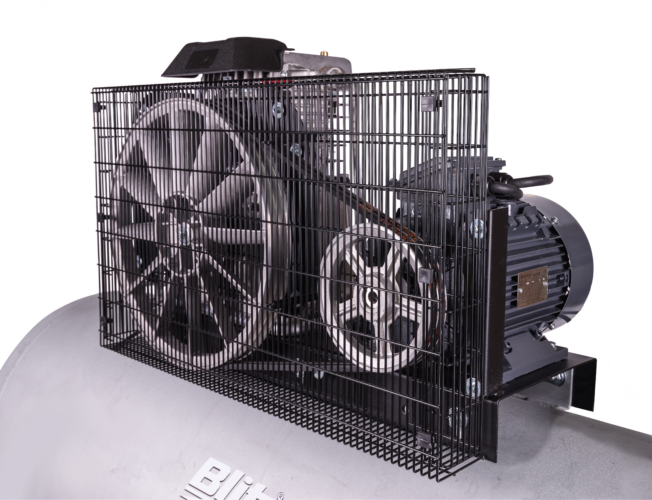

- BLITZ TWIN piston compressors are manufactured to a high standard of quality. This includes the use of IP 54 rated electric motors with ISO F winding. Sufficient sizing guarantees power reserves in any case.

- Powerful compressed air aftercoolers provide low compressed air outlet temperatures for all TWIN piston compressors as standard. The effort for further compressed air preparation is thus greatly reduced.

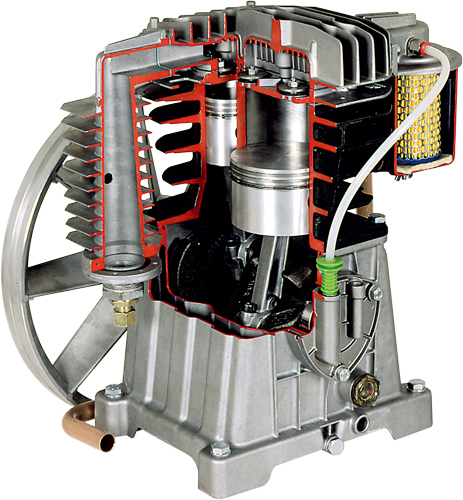

- TWIN piston compressors are almost consistently manufactured in an elaborate 2-stage design. Low thermal and mechanical loads lead to a much better efficiency overall and an energy saving of about 25%.

- The standard full galvanizing of the pressure vessel significantly increases the longevity and thus the value of the TWIN piston compressor.

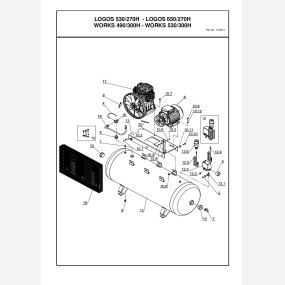

- Pressure vessel with hand hole (manufactured according to AD2000): The service-friendly design of the TWIN pressure vessel with integrated hand hole minimizes the effort of recurring TÜV (technical inspection agency) inspections and facilitates its cleaning.

- The low speed and the large swept volume of the TWIN piston compressors (on average around 1000 rpm for V-belt-driven systems) guarantee a long service life, low wear, maximum smoothness and high efficiency.

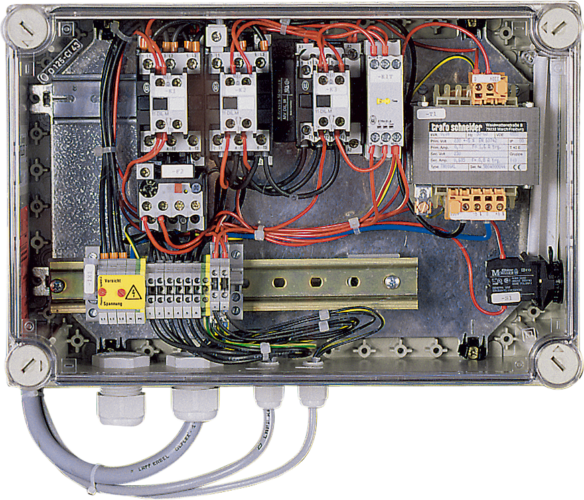

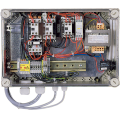

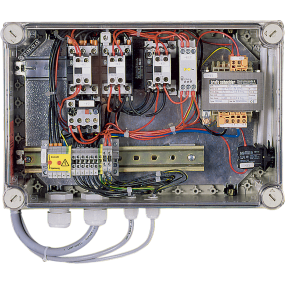

- Star-delta connection fully wired (standard as of 5.5 kW). Due to the assembly and functional testing in the factory the otherwise customary costs for on-site installation are completely eliminated. A big advantage over loosely supplied ”control kits”.

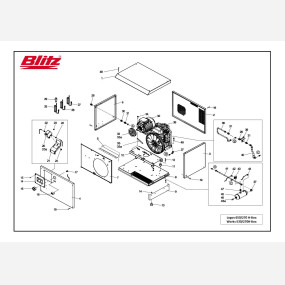

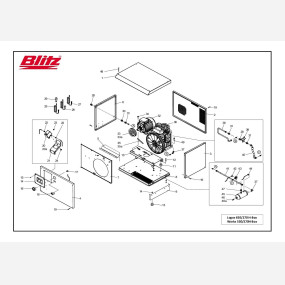

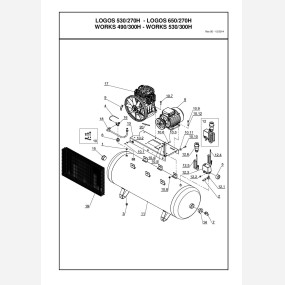

- Interior views: The ”heart” of each TWIN compressor in cross-section.

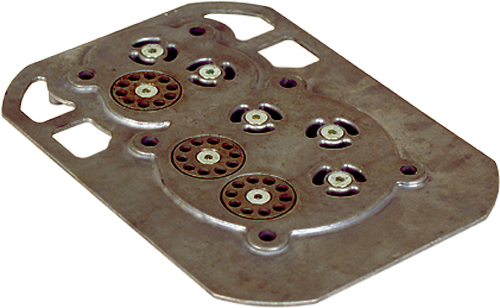

- Maintenance-free reed valves: The combination valve plates for 2-stage compression excel through their long service life and energy-saving efficiency.

Accessory:

- Refrigerant type dryer – for effective preparation of the compressed air. Dry compressed air without corrosive water content is the foundation for an economical compressed air station.

- Filter – effectively releases the compressed air from solid particles. A variety of filter combinations allow using the compressor in many different application environments.

- Oil water separator – the cost-effective preparation of condensate. Only the oil fractions need to be disposed of, whereas the water may be drained into the sewage system.

- Condensation drain – in an electronic, level controlled design for fully automatic dewatering of compressed air reservoirs.

In order to meet all installation requirements, there are stationary TWIN piston compressors with horizontal and vertical compressed air reservoir. A vertical installed pressure vessel makes them perfect for small rooms and workshops. For areas that are particularly sensitive to noise we provide designs with sound reduction hoods.

WORKS H BOX/LOGOS H BOX WITH NOISE REDUCTION HOOD – The logical addition to effective noise reduction.

HIGH POWER FOR EXACTING DEMANDS IN THE WORKSHOP AREA

TWIN: The powerful compressor for compressed air users with high standards and daily application needs. The wide range of applications of the TWIN piston compressors is the reason for the large variety of products. TWIN piston compressors come in oil-lubricated and oil-free versions.

VERSA: The high-performance compressor – designed for highest industrial demands.

VERSA piston compressors from BLITZ are available in oil-lubricated and oil-free versions as well as high-pressure and after-pressure compressors. In this respect, our separate brochures provide comprehensive information.

FOR NEARLY 100 YEARS…

A SYNONYM FOR COMPRESSED AIR

The construction of compressors has a long tradition at Blitz. With nearly 100 years of experience in compressed air and highly dedicated employees, we focus on designing and implementing new compressor and compressed-air conditioning technologies.

Innovative ideas, professional implementation and convincing product quality have established the outstanding reputation of Blitz compressors and predominantly ensure one goal: Satisfied customers.

The right offer for your needs: Based on your compressed air requirements, Blitz compressors assemble the right installations and systems in the best possible combination for you.